The burst is a very sudden event that creates a violent flow and shock wave. It sets the ambient environment to be identical to the result of a previous calculation.

In Flow Simulation, this is called a Transferred Boundary Condition.

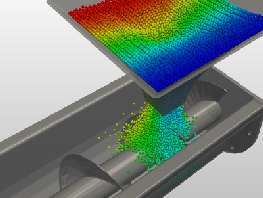

Since the burst happens inside the original domain, but is limited to a much smaller area, we’ll use a sub-study to calculate the burst more quickly and with more detail. To simulate the burst, we’ll create a spherical model of the shell at the shell burst coordinates and use it to generate a new study. Knowing the time delay of the fuse, we can quickly find the shell coordinates when it explodes. The shell position is shown graphically in SOLIDWORKS, or can be exported to data curves in Excel for further analysis. Since the particle is being injected into a flow environment that is already solved, it calculates very quickly. The Particle Study setup is easy, with another simple wizard prompting the user for required inputs. Here we’ll use it to simulate a single shell being launched up into the air, and then again to see where the various particles go after they are ejected from the shell. We more commonly use this tool for dust, mist, or sediment in engineering flows, to see how it will be distributed or where it might settle and create a residual deposit. Once the domain is set, simply run the study.įlow Simulation can inject spherical particles into a completed flow result using a Particle Study. This can be done graphically on screen, by dragging the arrow handles or by editing the definition of the domain just make sure it is big enough for the blast diameter. Using the study wizard, we’ll specify an external study with gravity, air, and a slight breeze to simulate our launch zone.Īfter the wizard is completed and the environment is set, the only additional step is to define the Computational Domain to be large enough to encompass the shell. Before we can launch the shell and see how it is affected by wind, we need to setup the environment with an external flow study. We need a simple model of a tube to start even a simple representation will work because the real activity is taking place in the air above. Let’s run through the setup of the first study. We’ll use this information to plan a big fireworks display in SOLIDWORKS and in the back yard. We wondered just how closely we could recreate the effect, and we also had a few specific questions to answer such as how much the wind will move the shell off course, and what impact the angle of the tube will have on the final trajectory. NET Framework Version:9 ASP.NET Version.In honor of America’s Independence Day, we decided to simulate an aerial fireworks display in SOLIDWORKS Flow Simulation. Page.ProcessRequestMain(Boolean includeStagesBeforeAsyncPoint, Boolean includeStagesAfterAsyncPoint) +1532 _Load(Object sender, EventArgs e) in C:\Users\TheWallaces\Documents\Visual Studio 2015\Projects\GoKB\GoKB\:273 Information regarding the origin and location of the exception can be identified using the exception stack trace below.

Please review the stack trace for more information about the error and where it originated in the code.Įxception Details: System.NullReferenceException: Object reference not set to an instance of an object.Īn unhandled exception was generated during the execution of the current web request. Description: An unhandled exception occurred during the execution of the current web request. Object reference not set to an instance of an object.

0 kommentar(er)

0 kommentar(er)